Simplify Your System with Process Skid Packages & Premium Hy-Lok Fittings

FPSO in Malaysia: Advantages, Costs, and How It Supports Offshore Operations

May 30, 2025

Common Types of Valves in Malaysia: Which Is Right for Your System?

May 30, 2025Across Malaysia’s industrial sectors, businesses increasingly prioritise modular and efficient systems to optimise operations.

One solution gaining momentum is using process skid systems—compact, prefabricated units engineered to streamline operations across various industries.

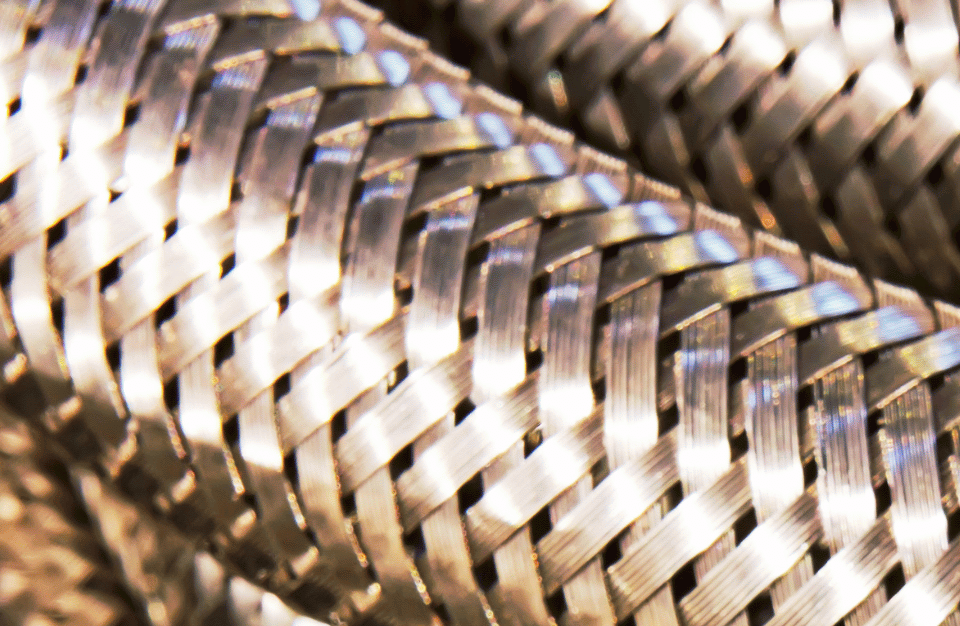

While the design and structure of these systems are important, the reliability of each component plays a pivotal role in ensuring seamless performance. Among the most trusted components are Hy-Lok fittings, known for their precision and industrial-grade durability.

This article explores how process skids work, their applications, and why quality fittings like Hy-Lok are essential to their success.

Key Takeaways

- Process skids are pre-assembled, modular process systems that perform specific industrial functions and integrate easily into existing operations.

- Integrating process skids improves installation speed, safety, cost-efficiency, and scalability for industrial systems.

- A process skid manages core operations, while a sampling skid extracts samples for quality monitoring without disrupting the process.

- Common types of process skids include chemical, oil & gas, FPSO, water treatment, HVAC, and power generation units.

- Hy-Lok fittings enhance process skid performance by ensuring leak-free process connections, corrosion resistance, and high-pressure reliability.

- Key considerations include system compatibility, material selection, regulatory compliance, ease of maintenance, and component quality.

What Is a Process Skid and How Does It Work?

A process skid is a pre-engineered, self-contained system that consolidates multiple components—such as pumps, valves, instruments, and piping—into a single, compact frame.

Traditional systems often require complex on-site controlled assembly, whereas process skids are fabricated off-site in controlled environments and delivered as fully assembled units.

This modular approach allows quicker deployment, better quality control during skid fabrication procedure, and simplified integration into existing infrastructure.

Once installed, process skids operate as part of a larger process flow, handling specific tasks like mixing, sampling, filtration, or chemical dosing, depending on their design and purpose.

Why Your Business Should Invest in Process Skids

Investing in process skids provides practical and long-term operational advantages for businesses seeking to modernise their production systems. Below are the key benefits:

| Benefit | Description |

| Faster Installation | Pre-assembled skids help achieve shorter project timelines by minimising on-site setup time and accelerating deployment. |

| Cost Efficiency | Minimises on-site errors and labour costs, ensuring better budget control. |

| Consistent Quality | Fabricated in controlled environments with strict quality assurance checks. |

| Compact, Modular Design | Space-saving and easy to fit into existing layouts or constrained facilities. |

| Improved Safety | Reduced on-site work lowers risks and potential hazards during installation. |

| Easy Scalability | Modular units allow for simple upgrades, reconfiguration, or expansion. |

These benefits make process skids an increasingly popular solution for businesses seeking streamlined, efficient, and safe process integration.

Process Skid vs Sampling Skid: What Sets Them Apart

Both systems are modular and pre-assembled, but they serve distinct roles. A process skid is built for core production tasks, while a sampling skid supports quality monitoring.

The process skid integrates into the main workflow to perform functions like mixing or pumping. In contrast, the sampling system integration operates alongside it, extracting samples for testing without halting operations.

Each plays a specific part—one drives the process, the other keeps it in check.

Explore the Right Process Skid Types to Optimise Your Operations

Industrial process skids are engineered for various functions depending on industry needs. Each type is designed to handle specific operations while maintaining a compact and modular setup.

Below are the most common types used in industrial environments:

| Type of Process Skid | Function & Application |

| Chemical Processing Skid | Used for mixing, dosing, and reaction control in sectors like pharmaceuticals, food and beverage processing, and petrochemicals. |

| Oil and Gas Skids Package | Handles filtration, separation, metering, and gas compression in upstream and downstream operations. |

| FPSO Skid Package | Designed for Floating Production Storage and Offloading (FPSO) units, integrating piping, instrumentation, and controls. |

| Water Treatment Skids | Used in industrial and municipal settings for filtration, softening, reverse osmosis, and chemical dosing. |

| HVAC Skid Package | Contains pumps, boilers, chillers, and control systems designed to support heat exchange processes for efficient heating and cooling in buildings and facilities. |

| Power Generation Skid | Includes generators, control panels, and switchgear to provide portable or backup power for industrial applications. |

These process skids enable industries to deploy specific systems more quickly, safely, and cost-effectively—without compromising on quality or compliance.

Want to understand how process skid and sampling skid systems are used in FPSO operations? Explore our in-depth guide on FPSO applications.

Boost Process Skid Reliability with Hy-Lok Fittings

A well-designed process skid requires dependable components to maintain safety, consistency, and operational efficiency. Hy-Lok fittings contribute significantly by offering precise, high-performance connections built for industrial demands.

| Feature | How It Enhances Performance |

| Leak-Free Sealing | Precision engineering delivers secure connections in systems such as fluid conditioner units, reducing the risk of fluid or gas leaks. |

| Corrosion Resistance | Durable materials like stainless steel protect against wear, extending service life. |

| High Pressure & Temperature Tolerance | Built to withstand extreme process conditions without compromising safety. |

| Quick & Easy Installation | Time-saving design simplifies setup and maintenance, reducing downtime. |

| Versatile Compatibility | Suitable for various process skid types—chemical dosing, sampling, filtration, and more. |

| Compliance with Global Standards | Meets international safety and performance certifications for industrial use. |

Discover Flexy’s full range of Hy-Lok fittings, including DBB valve and tube connectors, designed for reliable industrial performance.

Plan Smarter: What to Consider Before Installing a Process Skid

Successful process skid integration starts with strategic planning—not guesswork. Factoring in the following considerations can help ensure long-term efficiency and compatibility:

| Consideration | Why It Matters |

| Process System Compatibility | The skid must integrate seamlessly with existing pipelines, instrumentation, and control systems. |

| Material Selection | Materials should be chosen based on the media handled, operating temperature, and pressure range to avoid corrosion or breakdown. |

| Regulatory Compliance | Skids must adhere to Malaysian and international standards to ensure safety, efficiency, and certification readiness. |

| Ease of Maintenance | Skid layout should allow for safe and straightforward access to components for inspection, servicing, and part replacement. |

| Component Quality | Using high-performance parts like Hy-Lok fittings helps prevent leaks, minimise downtime, and ensure operational stability. |

Considering these factors early on will lead to smoother installation, safer operation, and better ROI from your skid investment.

Curious about the types of valves to consider when integrating a process skid? Learn how the right valve selection can enhance system performance and safety.

Streamline Your Skid Projects with Flexy’s Industrial Solutions

Flexy supports businesses in Malaysia with comprehensive products and services tailored for process skid and sampling skid systems.

The team works closely with clients at every stage—offering dependable solutions that align with operational goals and technical requirements.

| Service Area | What Flexy Offers |

| Hy-Lok Fittings Supply | A complete range of high-performance fittings including tube connectors, DBB valves, needle valves, and manifolds built for process-critical operations. |

| Product Compatibility | Expert guidance to match fittings and accessories with specific skid designs, operating conditions, and industry standards. |

| Custom Process Skids Solutions | Tailored product recommendations and layout support based on unique project needs and flow requirements. |

| Technical Support | Consultation on installation best practices and maintenance planning to ensure optimal system longevity. |

| Reliable Delivery | Fast and efficient supply chain management to ensure timely delivery across Malaysia. |

Flexy combines high-quality components with hands-on expertise to help businesses build process skids that perform reliably and meet industry standards.

Conclusion

Process skid systems provide a practical way for businesses to improve efficiency, ensure safety, and support modular expansion. The quality of each component—especially critical fittings—directly impacts overall system performance and durability.

Flexy offers a strong combination of technical know-how and industrial-grade products to help Malaysian companies implement reliable, leak-free process skid and sampling skid setups.

Contact Flexy for personalised advice and high-quality solutions, including Hy-Lok fittings designed for process-critical operations.