FPSO in Malaysia: Advantages, Costs, and How It Supports Offshore Operations

Simplify Your System with Process Skid Packages & Premium Hy-Lok Fittings

May 30, 2025Malaysia’s offshore oil and gas industry continues to expand into deeper and more remote waters, driving demand for flexible, efficient production solutions.

Among these, FPSOs have emerged as a critical asset—adaptable to various environments and capable of sustaining long-term operations at sea.

As industry players seek scalable infrastructure with lower risk and faster deployment, FPSOs are becoming an increasingly strategic choice in Malaysia’s energy landscape.

Key Takeaways

- An FPSO is a floating vessel that processes, stores, and offloads oil and gas extracted from offshore fields.

- FPSOs offer mobility, reduced infrastructure costs, and faster deployment for offshore production.

- They handle onboard production, storage, offloading, utilities, and system control.

- Unlike FSOs, which only store and offload, FPSOs process hydrocarbons directly at sea.

What is FPSO?

FPSO stands for floating production storage and offloading units. It is a maritime vessel designed to receive hydrocarbons from subsea wells, perform initial processing onboard, and store the processed oil temporarily until it can be transferred to shuttle tankers.

FPSOs are typically converted oil tankers or purpose-built vessels, offering a standalone solution for offshore oil fields where onshore pipelines or infrastructure are unavailable. Their flexibility and self-sufficiency make them ideal for remote offshore operations.

Equip Your FPSO Vessel with Flexy’s Offshore-Ready Solutions

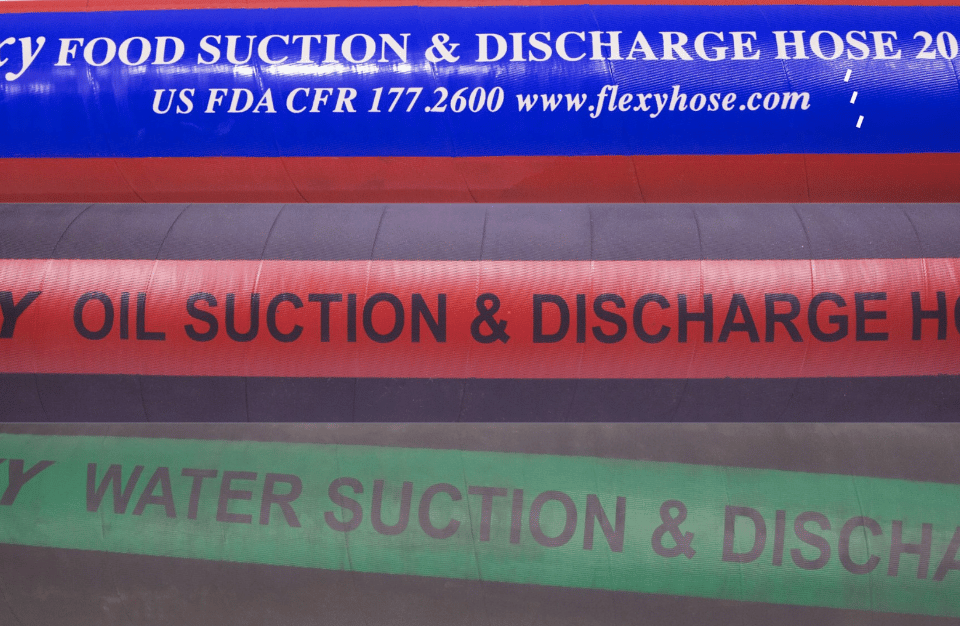

FPSO operations demand reliable, durable, and high-quality components to ensure uninterrupted production, processing, and offloading system.

Flexy, a trusted valve, fittings and hose supplier, provides a comprehensive range of industrial products and systems that support every stage of an FPSO’s lifecycle:

| Product/Service | Application in FPSO Operations |

| Industrial Hoses & Couplings | Used for critical fluid transfer systems, including crude oil, gas, water, and chemicals. Built to withstand extreme offshore conditions. |

| Pigging Systems | Ensures efficient pipeline cleaning and maintenance, reducing downtime and enhancing flow assurance. |

| Manual & Actuated Valves | Manual valves provide basic, reliable control for maintenance and low-risk systems.Actuated valves are vital for automation, safety, and rapid control in critical areas like hydrocarbon flow, gas processing, and emergency shutdown systems. |

| Instrument Fittings & Valves | Instrument fittings ensure leak-tight, vibration-resistant connections in small-bore tubing systems.Instrument valves are used to control or isolate pressure and flow to instruments like transmitters, gauges, and analysers. |

| Technical Support & Consultation | Flexy’s team offers product selection guidance, system integration advice, and after-sales support tailored to offshore requirements. |

With proven industry experience and a commitment to quality, Flexy helps FPSO operators optimise safety, efficiency, and performance—meeting the operational demands of Malaysia’s offshore oil and gas sector.

Why Choose an FPSO Vessel? 5 Key Benefits for Offshore Operations

An FPSO vessel offers several strategic advantages that make it a preferred solution for offshore oil and gas fields, especially in remote or deepwater locations:

- Mobility and Redeployment

FPSO vessels can be relocated to different oil fields once production at a site ends, maximising asset utilisation and reducing long-term investment risks.

- Reduced Infrastructure Needs

With onboard processing and storage, FPSO vessels eliminate the need for costly subsea pipelines and fixed platforms, lowering upfront capital expenditure.

- Faster Project Turnaround

Compared to building fixed facilities, deploying an FPSO vessel typically takes less time, enabling quicker access to production and revenue.

- Operational Efficiency in Harsh Environments

FPSOs are designed to operate independently in challenging marine conditions, ensuring reliable performance even in areas without support infrastructure.

- Scalability and Flexibility

They can be customised to suit field-specific requirements, offering flexibility in storage capacity, processing capabilities, and lifespan.

These benefits make FPSO vessels a smart investment for operators aiming to optimise offshore production while managing costs and deployment speed.

How an FPSO Vessel Supports End-to-End Offshore Oil Production

An FPSO plays a central role in the offshore production chain by handling various essential tasks directly at sea. Its design supports end-to-end operations without needing fixed platforms or onshore processing facilities. Key activities include:

| Function | What It Does | Why It Matters for Offshore Operations |

| Production & Processing | Separates crude oil, gas, water, and sediments from well fluids. | Enables immediate crude oil treatment of extracted hydrocarbons without requiring an onshore facility. |

| Crude Oil Storage | Holds processed oil in onboard cargo tanks. | Allows uninterrupted production even when transport tankers are delayed. |

| Offloading Operations | Transfers stored oil to shuttle tankers or export vessels. | Ensures continuous export and revenue generation with minimal downtime. |

| Utility & Support Systems | Includes power generation, water treatment, safety, and emergency systems. | Supports full operational independence in remote offshore environments. |

| Monitoring & Control | Manages production, offloading, and system integrity in real time. | Enhances safety, optimises output, and ensures regulatory compliance. |

Together, these functions enable the FPSO to serve as a fully operational floating facility—critical for offshore oil and gas production in Malaysia and beyond.

Explore high-quality Hy-Lok fittings designed for process skid systems—optimising FPSO operations with improved safety, faster installation, and greater efficiency.

FPSO vs FSO: What’s the Difference?

Although FPSO and FSO vessels support offshore oil and gas operations, their roles, capabilities, and applications differ significantly depending on project requirements:

| Feature | FPSO (Floating Production Storage and Offloading) | FSO (Floating Storage and Offloading) |

| Primary Function | Processes, stores, and offloads hydrocarbons. | Only stores and offloads crude oil or gas. |

| Processing Capability | Equipped with production and separation systems. | No onboard processing systems. |

| Use Case | Ideal for remote or deepwater fields without existing infrastructure. | Used alongside fixed or nearby processing platforms. |

| Flexibility | Offers complete offshore production solution. | Acts as a storage facility supporting other installations. |

| Cost | Higher upfront investment due to processing equipment. | Lower capital cost, simpler setup. |

Breaking Down the Cost of an FPSO: What Influences Your Investment

FPSO costs can vary significantly based on vessel type, field complexity, and project scale. Here are the main factors that impact the total investment:

| Cost Component | Details |

| Construction/Conversion Cost | Ranges from USD 500 million to over USD 2 billion. Costs depend on whether the FPSO is a new build or a converted oil tanker, and on the onboard processing systems required. |

| Operational Cost | Includes staffing, fuel, logistics, maintenance, and inspections. Ongoing OPEX varies by project scale and location but can run into tens of millions annually. |

| Project Complexity | Challenging environmental conditions—such as deepwater locations, harsh weather, or remote sites—typically lead to higher design and engineering costs. |

| Contracting Structure | Leasing an FPSO through an EPC or FPSO operator may reduce upfront capital expenditure for field operators. Ownership typically comes with higher initial investment but longer-term control. |

Explore the types of valves essential for FPSO systems and understand how each one impacts performance, safety, and overall project cost from Flexy valve supplier in Malaysia, such as manifold valve and tube fittings.

Conclusion

FPSO vessels have become a cornerstone of offshore oil and gas development, offering self-sufficient production and storage capabilities in remote marine environments.

As operations become more complex, system reliability and integration are key to maintaining uptime and safety.

Flexy offers specialised components and support designed for these challenges—from process skids to high-performance hoses, fittings, and pigging solutions.

Contact Flexy today to learn how our offshore-ready solutions can support your FPSO vessel operations and meet your project’s technical demands.